QD general bridge crane (hereinafter referred to as general crane) is designed and manufactured according to the standard GB/T14405-93, with the working class of A3~A6 and the working ambient temperature of - 25 ℃~+40 ℃.

This product is a general-purpose crane, which is mainly used in machinery manufacturing, assembly, warehouse and other places, and is not suitable for working under the following conditions:

A. Environment with explosion hazard and fire hazard;

B. Places with relative humidity greater than 85% and environments full of corrosive gases;

C. Lift molten metal, toxic substances and flammable and explosive substances.

The crane is operated by ground handle+remote control.

The structural features of this crane are as follows:

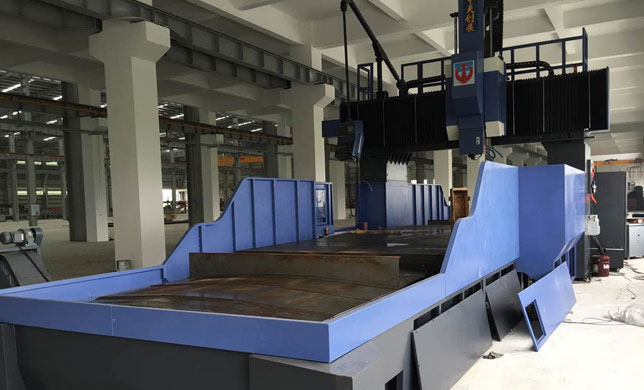

1. The general bridge crane is composed of two parts: crane and trolley. The trolley is equipped with lifting mechanism and trolley running mechanism, and the whole trolley runs along the trolley track installed on the main beam cover plate; The crane part is composed of crane bridge, etc. The crane bridge is equipped with crane traveling mechanism and trolley power transmission device.

2. The metal structure of the crane is composed of bridge and trolley frame, which is the bearing structure of the crane. The bridge is composed of main beam, end beam, walkway and guard rail. The main beam and end beam are welded into a box-shaped section structure by steel plates, with sufficient strength, rigidity and stability to ensure the safe operation of the crane.

3. The transmission mechanism of crane mechanism consists of lifting mechanism, trolley traveling mechanism, crane traveling mechanism, etc

Three parts.

4. The electric drive part is composed of electrical equipment and electrical circuit. Electrical equipment includes various mechanisms

Motor, brake drive device, electrical control device and electrical protection device; Electrical circuit

It is composed of main circuit, control circuit and warning signal circuit.