L-type bolt ship unloader is suitable for vertical type and large inclination to transport dry materials such as cement, fly ash, mineral powder, grain, fertilizer, oil bran, feed, chemical raw materials, etc., which are powdery, small granular, non-viscous and have a loose density of not more than 1.3t/m3. The material temperature shall not exceed 80 ℃ generally. The vertical screw ship unloader is not suitable for conveying bulky and viscous materials, nor for conveying materials with loose density less than 0.5t/m3 and strong fluidity.

characteristic

High efficiency: due to the use of forced feeder and high speed screw, the reclaiming speed is fast and the unloading capacity is large;

Energy saving and environmental protection: low energy consumption, 15~20% of that of pneumatic ship unloader; Its support structure is advanced, and its rotation is flexible, and its noise is very low; Because the reclaiming and feeding are carried out in a fully closed system, there is no dust and loss, and no dust and noise pollution will be caused to the surrounding environment;

Stable and reliable operation and low cost: only one person is required to operate the controller while observing the change of the material layer in the cabin, which saves labor and unloading time and greatly saves the operation cost;

Convenient maintenance: all transmission parts of the screw ship unloader need to be repaired are equipped with working platforms. When maintenance is needed, it can be carried out as long as the replacement spare parts and corresponding tools are prepared, without the need for professional lifting equipment.

Applicable occasions and installation methods

Inland river wharf

Medium and small seaport terminals

Floating dock

a ship

4�、 Specifications

According to the unloading volume: 50m3/h, 100m3/h, 150m3/h, 200m3/h, 300m3/h

5、 Usage

Fixed rotary type: it is installed on the fixed foundation of the quayside, and relies on the horizontal arm to rotate around the rotary tower and extract the material with the vertical feeder.

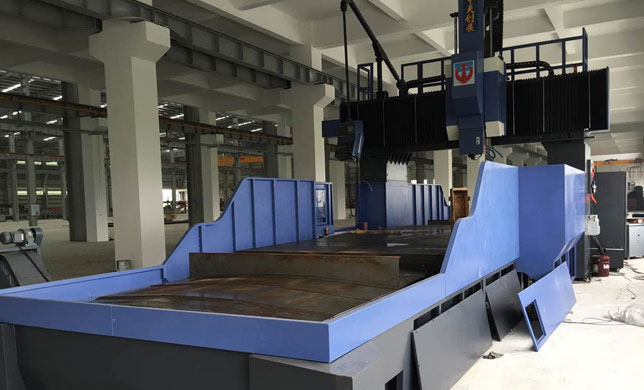

Mobile type: installed on the gantry, the gantry can travel along the rail parallel to the river bank, and the reclaiming movement adds a gantry travel action. More convenient.

Vehicle-mounted type: it is installed on a special vehicle. The vehicle can walk freely and work at multiple points.

Shipborne type: installed on a special ship, which can move on the channel and load and unload on the water.