The bridge-type grab ship unloader is a kind of ship unloading equipment with low investment and quick effect developed for the bulk material unloading operation at the terminals of small and medium-sized ports. The operation object ship is a 3000-ton river barge, taking into account the 5000-ton river and sea barges, and uses a four-rope grab for bulk material unloading operation. The machine has advanced performance, light weight, high efficiency, stable operation, simple operation, safety and reliability, convenient maintenance, beautiful appearance, and the performance index of the whole machine has reached the domestic level.

The bridge-type grab ship unloader is applicable to the coal unloading operation of small and medium-sized port ships or power plant wharf ships, with fast speed and high efficiency. This model can run on the track, and the clearance under the gantry can pass through the transport vehicles. The grab bucket will grab the bulk coal from the ship and then unload it to the conical hopper. It is sent to the belt conveyor on the wharf through the hopper outlet and then to the storage yard. The front girder can be used for pitching.

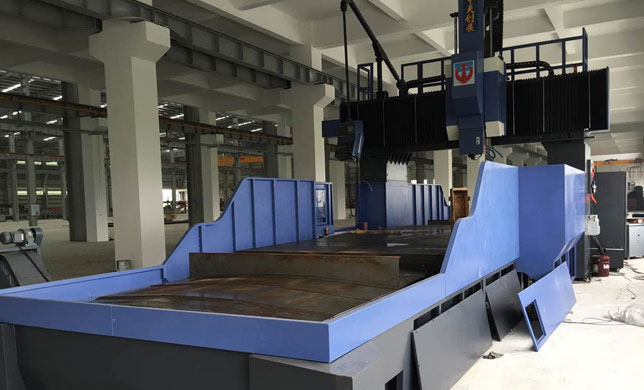

Structural features

It is composed of trolley, grab, machine room, electrical control system, trolley operation, lifting opening and closing mechanism, dust-proof water spray device, hopper, top rail anchor device, wind-proof mooring cable, crane operation mechanism, power cable drum, anti-material falling baffle, dust removal system, overload limiter, wind meter, lightning protection, fire protection device, various safety protection measures and alarm devices, overall metal structure and other main components.

The machine has the following functions: the grab enters the cabin - the grab is closed to dig materials - the grab is lifted out of the hatch - the trolley runs over the hopper set in the span of the ship unloader and then the grab is opened to discharge materials - the materials fall into the hopper, pass through the vibrating feeder at the lower part of the hopper, and then pass through the belt conveyor inside the machine to the wharf along the elevated belt conveyor. The whole process can be operated manually or semi-automatically. The environmental protection mode of the machine is: the surface water is supplied to the water tank on the machine, and then the water is supplied to each spray point by the water pump. The crane running mechanism of the whole machine can walk along the riverside track, and can arbitrarily change the operation position parallel to the riverside. After the operation, lift the front girder to a fixed position, and set a safety hook to hook the front girder. This machine also has the function of lifting the cabin cleaning machinery from the wharf into the operation cabin without unloading the grab.

The lifting, opening and closing of the ship unloader and the trolley traction drive device are driven by four-drum differential mechanism. The lifting, opening and closing of the grab and the trolley travel are all completed by various mechanisms fixed in the machine room. The main trolley has the function of lifting the scraper from the dock surface (or cabin) to the cabin (or wharf surface) without unloading the grab. Lifting, opening and closing, and trolley traction can be operated separately or jointly. Each drum of the four-drum mechanism can switch independently for rope change.